MESSYSTEME

Präzise Vermessung für die Verpackung unterschiedlichster Produkte

Unsere Messmaschinen richten sich vor allem an Unternehmen, die eine große Vielfalt unterschiedlicher Produkte verpacken und deren Abmessungen nicht manuell erfassen können.

Die Vorteile des Einsatzes

von Messmaschinen

Präzise Erfassung der tatsächlichen Abmessungen

Schnelligkeit und Anbindung an Verpackungsmaschinen

Optimierter und effizienterer Ablauf

Effiziente Verwaltung gemischter Chargen

MESSYSTEME

Die Perfektion einer maßgeschneiderten Lösung entsteht aus einem individuellen Ansatz, den Panotecs mechanische Exzellenz in integrierte Messstationen und Stationen zur Dimensionsprüfung von Produkten umsetzt, um einen reibungslosen und kontinuierlichen Verpackungsprozess zu gewährleisten.

Sie sind sich nicht sicher, welche Verpackungsmaschine für Ihre Bedürfnisse am besten geeignet ist?

Kontaktieren Sie unsThe choice of world leaders

Panotec auf der LogiMAT 2026: Virtuale und reale Verpackung erleben in Halle 6, Stand 6B57

Virtuelle und reale Verpackung mit Panotec auf der LogiMAT 2026 erleben

Unsere besten Weihnachtsgrüße

Ein aufrichtiger Wunsch, um das Jahr gemeinsam abzuschließen. Entdecken Sie die Botschaft des Jahres

Scrigno: Packaging for Doors and Cabinet Doors

Scrigno, a leader in designing and manufacturing counterframes for sliding doors and windows, partnered with Panotec to accelerate their production and refine their packaging process.

Denso case study: Packaging for automotive

Denso, a global leader in the production of automotive components, chose Panotec’s packaging systems to fully automate the creation of custom boxes, boosting process efficiency while significantly reducing operational costs and production times.

Pianca: Packaging for Assembled Furniture

Pianca, a renowned brand in high-end furniture design, partnered with Panotec to develop a fully automated packaging system that eliminated the use of polystyrene while enhancing productivity and the perceived quality of its products.

2B Case Study: Packaging for Shower Enclosures and Radiators

Box Docce 2B, a well-established company in the bathroom environment solutions sector, has chosen Panotec to optimise its packaging process and efficiently handle products featuring a wide dimensional variability.

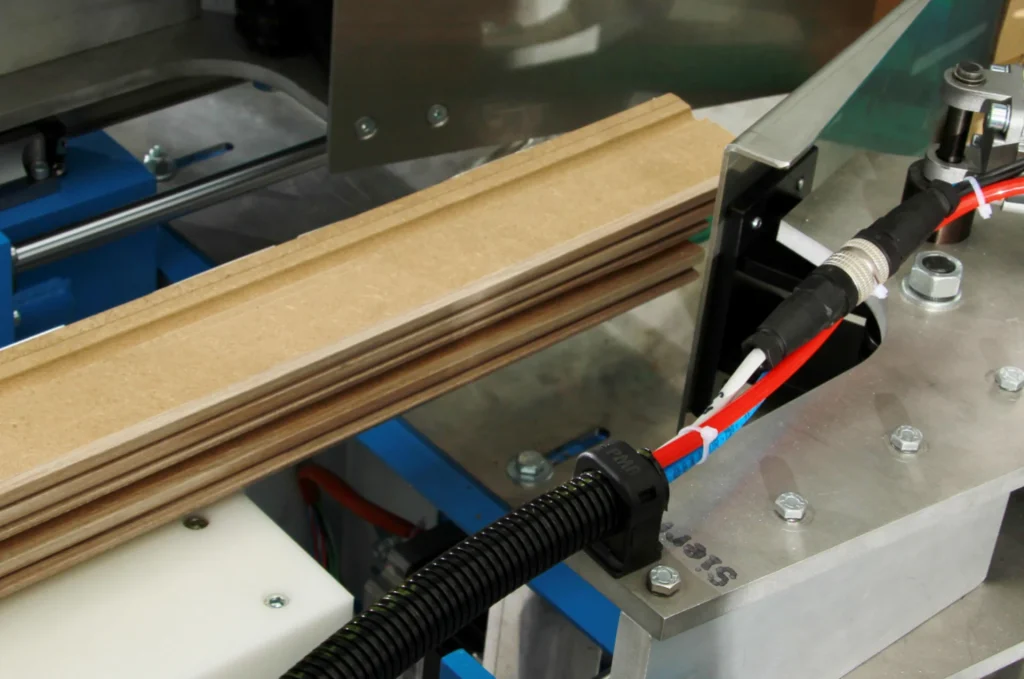

Packaging for jambs and profiles

The production of door frames, profiles, and related components requires solutions capable of optimizing the packaging process while efficiently managing highly variable formats and configurations. This case study illustrates how the adoption of advanced technologies can increase productivity, improve operational quality, and significantly reduce overall management costs.

Imab Group Case Study: Packaging for Flat-Pack Furniture

Imab, a key player in the furniture industry, transformed its packaging process with Panotec’s solutions, replacing shrink wrap with tailor-made cardboard boxes and introducing an automated system that optimized time, resources, and sustainability.

Packaging for electronic and hydraulic components

OEG, a German market leader in the distribution of heating, sanitary, and electrical solutions, chose Panotec’s OPERA Lines to optimize its packaging operations, streamline logistics, and boost efficiency during high-demand periods.

DCP Case Study: Packaging for Large Format Digital Print

DCP, a specialist in visual communication solutions for exhibitions, events, and architectural applications, chose Panotec to optimize its packaging flow and drastically reduce the warehouse space dedicated to box storage.

(Pflichtfelder mit * markiert)