MEASURING

SYSTEMS

Precision measurement for packaging different products

Our measuring machines are primarily intended for companies that need to package a wide variety of products and cannot manually track item dimensions.

The advantages of using

measuring machines

Accurate detection of real dimensions

Speed and interconnection with packaging machines

Optimized and more efficient flow

Efficient mixed-batch management

MEASURING

SYSTEMS

The perfection of a custom solution stems from a tailor-made approach, which Panotec mechanical excellence translates into integrated measuring stations and dimensional scanning stations for products, ensuring a smooth and continuous packaging process.

Not sure which Panotec machine is best suited to your needs?

CONTACT US NOW!The choice of world leaders

Is your Panotec Service Contract about to expire?

Renew before the expiry date and receive 1 additional month included on your renewed contract.

Panotec at LogiMAT 2026: Try Virtual and Real Packaging in Hall 6, Stand 6B57

Experience real and virtual packaging with Panotec at LogiMAT 2026

Our Warmest Season’s Greetings

A sincere wish as we close this year together. Unveiling our message for the year

Scrigno: Packaging for Doors and Cabinet Doors

Scrigno, a leader in designing and manufacturing counterframes for sliding doors and windows, partnered with Panotec to accelerate their production and refine their packaging process.

Pianca: Packaging for Assembled Furniture

Pianca, a renowned brand in high-end furniture design, partnered with Panotec to develop a fully automated packaging system that eliminated the use of polystyrene while enhancing productivity and the perceived quality of its products.

Packaging for electronic and hydraulic components

OEG, a German market leader in the distribution of heating, sanitary, and electrical solutions, chose Panotec’s OPERA Lines to optimize its packaging operations, streamline logistics, and boost efficiency during high-demand periods.

DCP Case Study: Packaging for Large Format Digital Print

DCP, a specialist in visual communication solutions for exhibitions, events, and architectural applications, chose Panotec to optimize its packaging flow and drastically reduce the warehouse space dedicated to box storage.

Denso case study: Packaging for automotive

Denso, a global leader in the production of automotive components, chose Panotec’s packaging systems to fully automate the creation of custom boxes, boosting process efficiency while significantly reducing operational costs and production times.

2B case Study: Packaging for Shower Enclosures and Radiators

Box Docce 2B, a well-established company in the bathroom environment solutions sector, has chosen Panotec to optimise its packaging process and efficiently handle products featuring a wide dimensional variability.

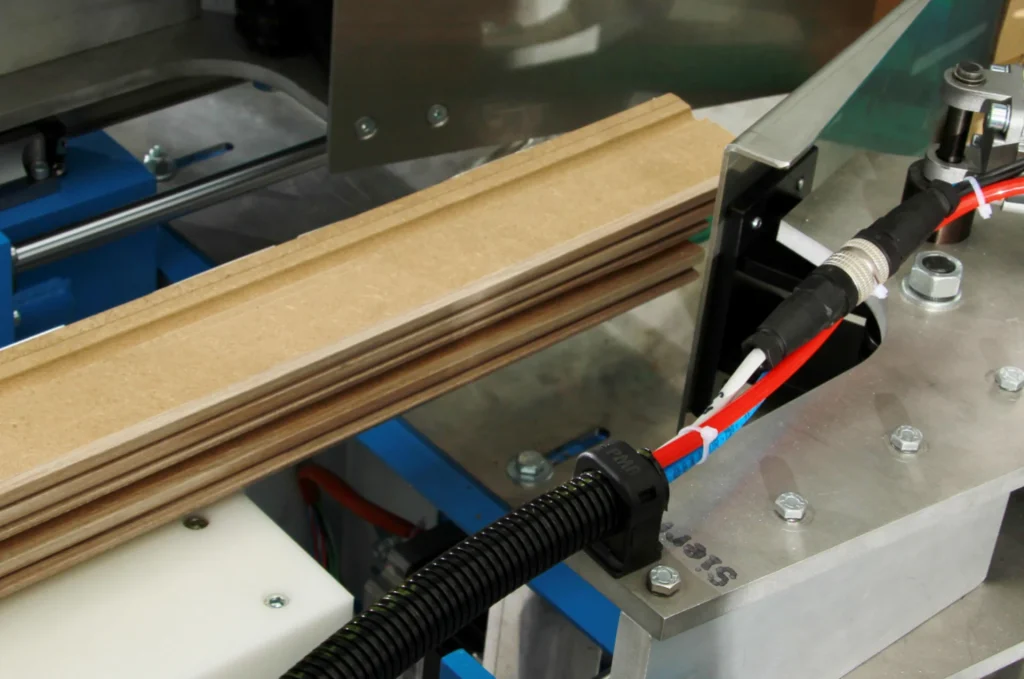

Packaging for jambs and profiles

The production of door frames, profiles, and related components requires solutions capable of optimizing the packaging process while efficiently managing highly variable formats and configurations. This case study illustrates how the adoption of advanced technologies can increase productivity, improve operational quality, and significantly reduce overall management costs.

(Required fields marked with *)