Nextpro

Nextpro is the ideal packaging machine for high variability and productivity requirements

A declaration of technological superiority that paves the way for a customised, efficient and flexible packaging process tailored to the challenges of the future. Thanks to its independent tooling units, Nextpro allows for higher execution speed than other packaging machines and guarantees the utmost productivity flexibility.

Suitable for:

- Large-sized, structured companies

- High productivity requirements

- Production of more than 10 boxes per minute

- High flexibility production (batch size 1)

- Numerous production sectors from furniture to e-commerce, from shower cubicles and automotive to digital printing

Find out how Nextpro can improve your company’s efficiency and productivity!

Suitable for:

- Large-sized, structured companies

- High productivity requirements

- Production of more than 10 boxes per minute

- High flexibility production (batch size 1)

- Numerous production sectors from furniture to e-commerce, from shower cubicles and automotive to digital printing

Find out how Nextpro can improve your company’s efficiency and productivity!

Work phases

Entry of box pattern and dimensions

Available in manual or automatic version (CSV file or link to management system)

Box cutting and creasing in seconds

The packaging machine automatically selects the best available cardboard to create the optimised box, minimising waste.

Customised product packaging:

MANUAL VERSION:

the operator manually packs products into customised boxe

AUTOMATIC VERSION:

automates your packaging area even more with our accessories

Features

Cardboard feeding

The packaging machines are fed by a continuous sheet of corrugated cardboard folded like a fan, known as a fanfold. If more than one fanfold slot is present, the machine automatically selects the most suitable cardboard width to optimise consumption.

Optional

Serrated creasing

Creasing with perforation in addition to Standard creasing: makes it easier for the operator to fold the cardboard, which also enhances its appearance.

Trim extraction and conveyors

Composed of:

- extractor to remove cardboard trim laterally

- conveyor belt to remove waste

End of cardboard sensors

A set of photocells that give an early warning that the cardboard pallet is running out.

Box code printing management

Integrated solution for printing codes, short descriptions or barcodes on the inner surface of the box by means of ink-jet marking with 12.7 mm HP print head.

Label printing management

Integrated label printing solution in combination with box production with network-connected thermal transfer printer.

Technical

data

Machine width/span

2.5 or 3.0

Productivity level

high

Boxes / min

over 10 / min

Boxes / day (batch production 1)

>1500 boxes

Boxes / day (in batches)

>3000 boxes

Cardboard feeding rate

48m / min

Cardboard feeding type

fanfold

Number of cardboard cassettes

up to 12 fanfolds

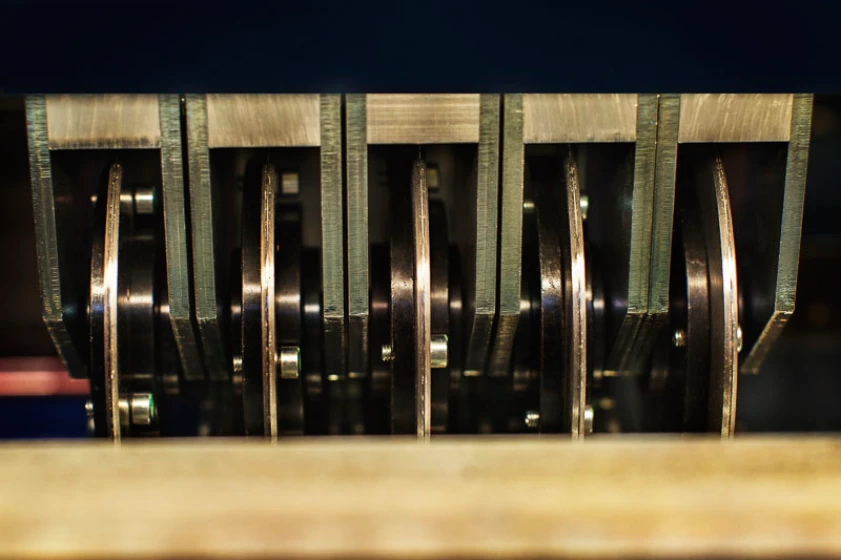

No. longitudinal cutting and creasing units

up to 24

Normal / serrated creasing

Normal / serrated

Cardboard trim management

available

Cardboard thickness

2 mm to 7 mm

Software

included

Interested?

Write us to request more information

(Required fields marked with *)