Operetta

The next generation of automation for customised packaging.

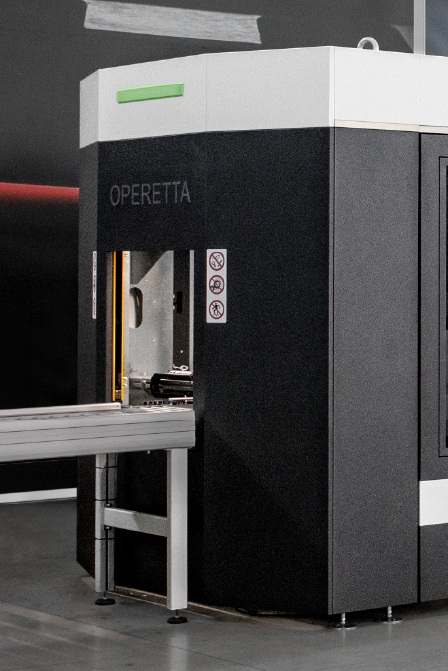

With a keen eye on the needs of e-commerce, logistics services and all companies handling high volumes of daily shipments, Operetta integrates into existing production processes with total flexibility.

OPERETTA is also perfectly suited for the packaging of multi-item orders and fragile, unstable products without the use of fillers and in extremely short lead times.

Key

benefits:

How does

it work

Goodbye damaged packages

The box is designed to be reinforced on all four sides to ensure excellent protection of the product during transport. The reinforced corners allow the boxes to be stacked on top of each other without becoming damaged or crushed by their weight.

The unique box design created by OPERETTA mirrors the configuration of the American FEFCO 0201 boxes, allowing smooth integration with standard taping machines available on the market.

Simplified process

thanks to OPERETTA’s automated technology, box handling and procurement times are minimised, allowing operators to focus exclusively on the order filling phase.

Interfacing with our volume optimisation software, QBOX, optimises the workflow by automatically calculating the optimal box size for multi-item orders and simplifies the operator’s task in later phases by providing precise product insertion instructions.

Find out how OPERETTA can integrate seamlessly into your packaging process to optimise time and resources!

TECHNICAL

DATA

Machine length

16.7 m

Machine height

2.8 m

Machine width

2.5 m

Maximum box dim.

Max: L 675mm / W 500mm / H 450mm

Minimum box dim.

Min: L 200mm / W 150mm / H 50mm

Maximum Productivity

15 pcs/min

Cardboard feeding

fanfold - 2 sizes: 400mm (min) and 800mm (max)

Cardboard type

Single wall B or E, Double wall E/E

Waste reduction

Automatic cardboard selector: maximum reduction of material waste

Interested?

Write us to request more information

(Required fields marked with *)