INSTALLATIONS D’EMBALLAGE PERSONNALISÉES

Automatisation de l’emballage conçue selon vos besoins

Grâce à une approche modulaire et évolutive, nous réalisons des installations entièrement personnalisables selon les besoins spécifiques du client : du niveau d’automatisation souhaité à l’intégration dans la disposition de production existante.

Les avantages de l’utilisation d’installations

automatisées pour l’emballage

Flux de production simplifié et flexible

Optimisation des ressources humaines

Meilleure protection du produit

Réduction des coûts

Meilleure qualité perçue

Personnalisable selon les besoins

INSTALLATIONS D’EMBALLAGE PERSONNALISÉES

Découvrez nos installations d’emballage personnalisées, conçues pour s’adapter parfaitement à vos besoins logistiques, productifs et d’aménagement.

Chaque solution est étudiée pour garantir l’efficacité opérationnelle et les économies, en optimisant le temps, les coûts et les ressources.

Au cœur se trouve une technologie modulaire et flexible, qui permet de configurer différents niveaux d’automatisation en fonction du volume de production, de l’espace disponible et des objectifs spécifiques de chaque entreprise.

Vous ne savez pas quel système d’emballage sur mesure est le plus adapté à vos besoins ?

Contactez-nous dès à présentThe choice of world leaders

Scrigno Case Study: Packaging for Doors and Cabinet Doors

Scrigno, a leader in designing and manufacturing counterframes for sliding doors and windows, partnered with Panotec to accelerate their production and refine their packaging process.

Denso case study: Packaging for automotive

Denso, a global leader in the production of automotive components, chose Panotec’s packaging systems to fully automate the creation of custom boxes, boosting process efficiency while significantly reducing operational costs and production times.

Pianca: Packaging for Assembled Furniture

Pianca, a renowned brand in high-end furniture design, partnered with Panotec to develop a fully automated packaging system that eliminated the use of polystyrene while enhancing productivity and the perceived quality of its products.

2B Case Study: Packaging for Shower Enclosures and Radiators

In this article, you will find our packaging solution for the shower box and sanitary ware sector, with the example of one of our successful clients: Box Docce 2B.

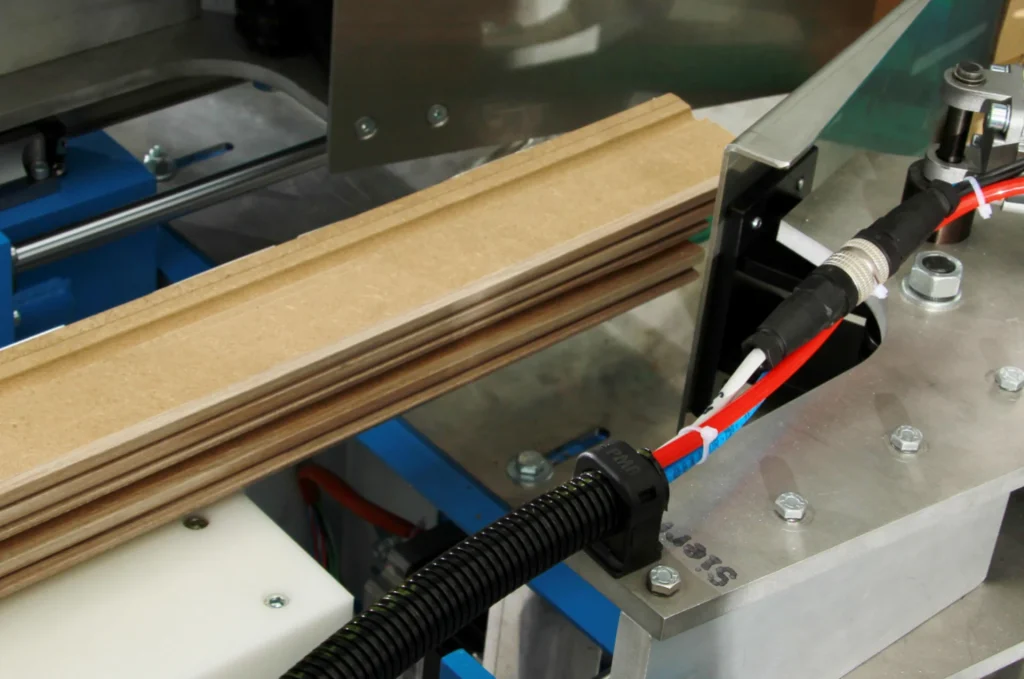

Packaging for jambs and profiles

The production of door frames, profiles, and related components requires solutions capable of optimizing the packaging process while efficiently managing highly variable formats and configurations. This case study illustrates how the adoption of advanced technologies can increase productivity, improve operational quality, and significantly reduce overall management costs.

Imab Group Case Study: Packaging for Flat-Pack Furniture

Imab, a key player in the furniture industry, transformed its packaging process with Panotec’s solutions, replacing shrink wrap with tailor-made cardboard boxes and introducing an automated system that optimized time, resources, and sustainability.

Packaging for electronic and hydraulic components

OEG, a German market leader in the distribution of heating, sanitary, and electrical solutions, chose Panotec’s OPERA Lines to optimize its packaging operations, streamline logistics, and boost efficiency during high-demand periods.

DCP Case Study: Packaging for Large Format Digital Print

DCP, a specialist in visual communication solutions for exhibitions, events, and architectural applications, chose Panotec to optimize its packaging flow and drastically reduce the warehouse space dedicated to box storage.

Philips Lighting Case Study: Packaging for Lighting Components

Philips Lighting, a global leader in lighting solutions for residential, commercial and industrial applications, chose Panotec to optimise packaging productivity and efficiently manage an extremely wide product range.

Panotec présente : GAOR Open House 2025 – 5e anniversaire et lancement de l’EVO 3.0

Panotec vous invite à un événement professionnel à Murcie (Espagne) pour célébrer le 5e anniversaire de GAOR et présenter la nouvelle génération d’emballage à la demande : EVO 3.0.

Le choix des leaders mondiaux

De nombreux leaders mondiaux nous ont choisis comme partenaire stratégique grâce à la qualité, la fiabilité et l’expertise que nous offrons dans la conception des meilleures solutions, exclusivement Made in Italy.

Scrigno Case Study: Packaging for Doors and Cabinet Doors

Scrigno, a leader in designing and manufacturing counterframes for sliding doors and windows, partnered with Panotec to accelerate their production and refine their packaging process.

Pianca: Packaging for Assembled Furniture

Pianca, a renowned brand in high-end furniture design, partnered with Panotec to develop a fully automated packaging system that eliminated the use of polystyrene while enhancing productivity and the perceived quality of its products.

Imab Group Case Study: Packaging for Flat-Pack Furniture

Imab, a key player in the furniture industry, transformed its packaging process with Panotec’s solutions, replacing shrink wrap with tailor-made cardboard boxes and introducing an automated system that optimized time, resources, and sustainability.

(Champs obligatoires marqués par *)